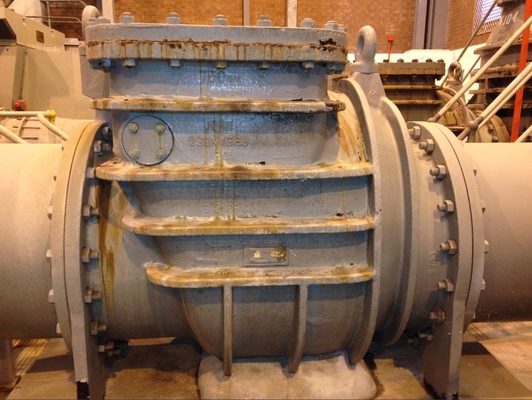

Industrial Low Pressure Check Valve / API 598 Stainless Steel Check Valve

Check Valve 150Lbs RF STL F6 Trim BB Swing Dia 4" Mat ASTM A 216 Grade WCB or WCC

CHECK VALVE, CARBON STEEL, SWING,

RAISED FACE FLANGE, 400 DEG F (DESIGN),

FLANGED RAISED FACE TO ANSI B16.5

CONFORMING TO LATEST EDITION OF API 6D

AND SUITABLE FOR SOUR SERVICE NACE MR0175,

MATERIAL SPECIFICATION SHALL BE AS PER CLAUSE 6.6 /

MAXIMUM HARDNESS HB197

BODY MATERIAL: CARBON STEEL

TYPE: SWING

CONFIGURATION: FULL BORE

CONNECTION: RAISED FACE FLANGE

TEMPERATURE RATING: 400 DEG F (DESIGN)

SPECIFICATION: AS API 6D

Specifications:

Swing Check Valve 8" 150# Flanged RF - B16.5 / B16.47 FB - Bolted Cover

Body Material: A216 WCB

Ball/Disc/Plug: F6 (13% Cr.) / Seat Ring : CS+Stellite 6

Body Gasket : 304+Flex Graphite, Bolting : A193-B7M / A194-2HM, NACE MR-01-75

Standards

Design and manufacture as BS1868, ANSI B16.34

Face to face dimensions as ANSI B16.10

End flange dimension as ANSI B16.5

Pressure-temperature ratings as ANSI B16.34

Pressure test as API 598

Applicable Medium: water ,gas,oil,and other causticity medium.

Test Pressure

|

Test Item

|

Shell Test

|

Seal Test

|

Back Seal Test

|

Air Seal Test

|

|

Medium

|

Water

|

Air

|

|

Unit

|

MPa

|

lbf/in2

|

MPa

|

lbf/in2

|

MPa

|

lbf/in2

|

MPa

|

lbf/in2

|

|

Pressure (Class)

|

150

|

3.1

|

450

|

2.2

|

315

|

2.2

|

315

|

0.5-0.7

|

60-100

|

|

300

|

7.8

|

1125

|

5.6

|

815

|

5.6

|

815

|

|

400

|

10.3

|

1500

|

7.6

|

1100

|

7.6

|

1100

|

|

600

|

15.3

|

2225

|

11.2

|

1630

|

11.2

|

1630

|

|

900

|

23.1

|

3350

|

16.8

|

2440

|

16.8

|

2440

|

|

1500

|

38.4

|

5575

|

28.1

|

4080

|

28.1

|

4080

|

Brief introduction:

The check valve is designed and manufactured according well to API 6D and ANSI B 16.34. It can

work in

high temperature and pressure circumstance. It also have the features of good appearance, nice

function and

superior. Widely used for petroleum, chemistry, water treatment industries.

Features:

- Resist friction

Valve disc is given enough intensity and rigidity. Disc sealing surface may be built up welded with

satellite alloy inlaid or other material responding to the users’ request.

- Agility of switch

Solid ping is precisely installed and provided with high intensity to ensure operational performance

and service life of valve.

- Sealing credibility

The check valve adopt swing configuration. All the sealing part inside the valve, so all exterior leak

may except the middle flange, and also the middle flange gasket may be different

according to pressure class.

- Distortion compensating

The disc and the hinge are connected between slippery spherical surface, and this makes the disc

can circumgyrate in a little angle and regulates the sealing capability.

Mail part & material

|

|

Item Name of parts

|

material

|

|

1

|

Body

|

WCB,CF8

|

|

2

|

Seat

|

304,A105+ satellite

|

|

3

|

Disc

|

304,A105+ satellite

|

|

4

|

Gasket

|

Graphite+304

|

|

5

|

Bonnet

|

WCB,CF8

|

|

6

|

Yoke

|

WCB,CF8

|

|

7

|

Hinge

|

WCB,CF8,2Cr13

|

|

8

|

Hinge pin

|

2Cr13,304

|

Main Connection Dimensions

|

Type

|

Size(mm)

|

Dimension(mm)

|

|

inch

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

z-Φd

|

H

|

|

H44H/W/Y-150Lb

|

1″

|

25

|

127

|

108

|

79.5

|

51

|

12

|

4-Φ15

|

90

|

|

11/2″

|

40

|

165

|

127

|

98.5

|

73

|

15

|

4-Φ15

|

115

|

|

2″

|

50

|

203

|

152

|

120.7

|

92

|

16

|

4-Φ19

|

150

|

|

21/2″

|

65

|

216

|

177.8

|

139.7

|

104.7

|

18

|

4-Φ19

|

160

|

|

3″

|

80

|

241

|

190.5

|

152.4

|

127

|

19

|

4-Φ19

|

180

|

|

4″

|

100

|

292

|

229

|

190.5

|

157

|

24

|

8-Φ19

|

220

|

|

5″

|

125

|

330

|

254

|

216

|

185.7

|

26

|

8-Φ22

|

280

|

|

6″

|

150

|

356

|

279

|

241.3

|

216

|

26

|

8-Φ22

|

340

|

|

8″

|

200

|

495

|

343

|

298.5

|

270

|

29

|

8-Φ22

|

400

|

|

10″

|

250

|

622

|

406

|

362

|

324

|

31

|

12-Φ25

|

460

|

|

12″

|

300

|

698

|

483

|

432

|

381

|

32

|

12-Φ25

|

530

|

|

14″

|

350

|

787

|

533

|

476.3

|

413

|

35

|

12-Φ29

|

580

|

|

16″

|

400

|

864

|

597

|

540

|

470

|

37

|

16-Φ29

|

600

|

|

18″

|

450

|

978

|

635

|

578

|

533.4

|

40

|

16-Φ32

|

650

|

|

20″

|

500

|

978

|

698 5

|

635

|

584

|

43

|

20-Φ32

|

700

|

|

24″

|

600

|

1295

|

813

|

749.3

|

692

|

48

|

20-Φ35

|

780

|

|

28″

|

700

|

1448

|

927

|

863.6

|

800

|

72

|

28-Φ35

|

850

|

|

30″

|

800

|

1524

|

984

|

914.4

|

857

|

75

|

28-Φ35

|

920

|

|

Type

|

Size(mm)

|

Dimension(mm)

|

|

|

inch

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

z-Φd

|

H

|

|

H44H/W/Y-900Lb

|

2″

|

50

|

368

|

216

|

165.1

|

92

|

38.5

|

8-Φ26

|

220

|

|

|

21/2″

|

65

|

419

|

244

|

190.5

|

104.7

|

41.5

|

8-Φ29

|

250

|

|

|

3″

|

80

|

381

|

241

|

190.5

|

127

|

38.5

|

8-Φ26

|

270

|

|

|

4″

|

100

|

457

|

292

|

234.9

|

157

|

44.5

|

8-Φ32

|

330

|

|

|

5″

|

125

|

559

|

349

|

279.4

|

185.7

|

51

|

8-Φ35

|

350

|

|

|

6″

|

150

|

610

|

381

|

317.5

|

216

|

56

|

12-Φ32

|

420

|

|

|

8″

|

200

|

737

|

470

|

393.7

|

270

|

63.5

|

12-Φ39

|

490

|

|

|

10″

|

250

|

838

|

545

|

469.9

|

324

|

70

|

16-Φ39

|

550

|

|

|

12″

|

300

|

965

|

610

|

533.4

|

381

|

79.5

|

20-Φ39

|

630

|

|

|

14″

|

350

|

1029

|

640

|

558.8

|

413

|

86

|

20-Φ42

|

680

|

|

|

16″

|

400

|

1130

|

705

|

615.9

|

470

|

89

|

20-Φ45

|

720

|

|

|

18″

|

450

|

1219

|

785

|

685.8

|

533.4

|

102

|

20-Φ51

|

750

|

|

|

20″

|

500

|

1321

|

855

|

749.3

|

584

|

108

|

20-Φ54

|

800

|

|

|

24″

|

600

|

1549

|

1040

|

901.7

|

692

|

140

|

20-Φ67

|

880

|

|

H44H/W/Y-1500Lb

|

2″

|

50

|

368

|

216

|

165.1

|

92

|

38.5

|

8-Φ26

|

222

|

|

|

21/2″

|

65

|

419

|

244

|

190.5

|

104.7

|

41.5

|

8-Φ29

|

260

|

|

|

3″

|

80

|

470

|

267

|

203.2

|

127

|

48

|

8-Φ32

|

270

|

|

|

4″

|

100

|

546

|

311

|

241.3

|

157

|

54

|

8-Φ35

|

330

|

|

|

5″

|

125

|

673

|

375

|

292.1

|

185.7

|

73.5

|

8-Φ42

|

370

|

|

|

6″

|

150

|

705

|

394

|

317.5

|

216

|

83

|

12-Φ39

|

440

|

|

|

8″

|

200

|

832

|

483

|

393.7

|

270

|

92

|

12-Φ45

|

510

|

|

|

10″

|

250

|

991

|

584

|

482.6

|

324

|

108

|

12-Φ51

|

570

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!