Fully Welded Floating Ball Valve For Underground Installation Minimum Flow Resistance

Floating Ball Valve Technical Specifications

Design standard: ISO14313 ,API 6D,BS 5351,GB/T 19672

Face to face standard: ASME B16.10,GB/T 12221

Flange ends: ASME B16.5,ASME B16.47 ,GB/T 9113

Fire safe design:API 6FA ,API 607

Pressure test:API 6D,API 598,GB/T 13927

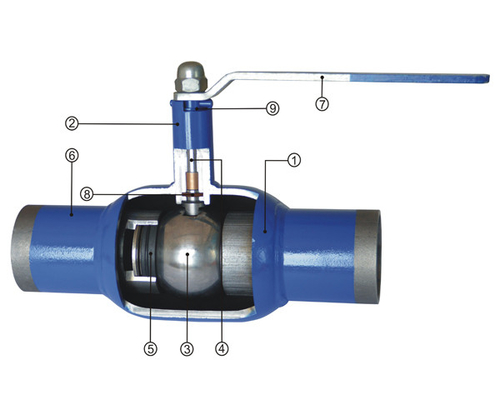

Product Description:

The fully-weled ball valve adopts forged material , welded body, instead of bolts and nuts,to aviod any potential leakage from body.

The forged body with regular structure and even thickness can avoid shrinkage cavities, pin holes, cracks, sand holes and other defects occurring to casted valves.

Technical Specifications

Design standard: ISO14313 ,API 6D,BS 5351,GB/T 19672

Face to face standard: ASME B16.10,GB/T 12221

Flange ends: ASME B16.5,ASME B16.47 ,GB/T 9113

Fire safe design:API 6FA ,API 607

Pressure test:API 6D,API 598,GB/T 13927

Simple structure with good tightness and small torque;

With a fully-welded valve body, full bore and the minimum flow resistance (zero actually);

Fire safe, anti-static and anti-blowout stem desjgn;

Valve seat function DBB, DIB-1, DIB-2;

Be able to be used for underground installation without corrosion of interior parts, therefore, it is the best application for petroleum and natural gas lines;

Service life up to 30 years. |

Floating Ball Valve Application:

Long distance pipe lines for petroleum, chemical industry, metallurgy, light industry, power station,

urban construction water supply, as well as oil, gas and natural gas transmission and so on

Body Material : ASTM A216 WCB

Ball and Trim Material : Stainless Steel

Lever Material : Forged steel with Zn coated

Seat Material : PTFE

Working Temperature : 05°C to 50°C

Working Pressure : 150 Psig./350 Psig.

Fluid to be handled : Natural Gas

(Odorized) containing 0.5% CO2 by volume.

API 6D Certificate

Description:

The ball valve is designed and manufactured according well to API 608. Floating ball when small caliber,

and fixed ball when large caliber.

It has fire protection structure and antistatic device. Widely used for petroleum, chemistry, water

treatment industries.

Features:

- Anti-blowout Structure of Valve Stem

When medium pass through the valve, the pressure in valve body may possibly push the stem out, or

when the valve is in repair, if there is pressure in the middle cavity, the stem or medium seems to easily

fly out upon disassembling the valve, which can cause injures to human beings, To prevent the

possibilities, a dummy club is packing and thrust bearing are burnt or packing is damaged due to other

causes, the pressure of medium in valve body will make the dummy club of valve stem in close contact

with the upper seal face of valve body. Thus to prevent medium leaking out from the damage packing

position.

- Reliable Seal Structure

The seat is made of PTFE. Because the contact area between seat and the ball will becomes more high

with rising of pressure of the middle cavity, Small Resistance ball valve has the smallest resistance of all

the valve, in the case of reduced bore, the resistance is little still.

-Prompt switch

The ball valve circumrotates in 90°,It work quickly to open or close.

|

Main Connection Dimensions

|

Type

|

Size(mm)

|

Dimension(mm)

|

|

inch

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

Z-Φd

|

H

|

W

|

|

Q41F/H/Y-150Lb

Q341 F/H/Y-150Lb

Q641 F/H/Y-150Lb

|

1/2″

|

15

|

108

|

89

|

60.5

|

35

|

12

|

4-Φ15

|

68

|

115

|

|

3/4″

|

20

|

117

|

98

|

70

|

43

|

12

|

4-Φ15

|

75

|

130

|

|

1″

|

25

|

127

|

108

|

79.5

|

51

|

12

|

4-Φ15

|

85

|

150

|

|

11/4″

|

32

|

140

|

117

|

89

|

64

|

13

|

4-Φ15

|

96

|

190

|

|

11/2″

|

40

|

165

|

127

|

98.5

|

73.2

|

15

|

4-Φ15

|

107

|

230

|

|

2″

|

50

|

178

|

152

|

120.7

|

92

|

16

|

4-Φ19

|

118

|

240

|

|

21/2″

|

65

|

190

|

177.8

|

139.7

|

104.7

|

18

|

4-Φ19

|

145

|

280

|

|

3″

|

80

|

203

|

190.5

|

152.4

|

127

|

19

|

4-Φ19

|

160

|

310

|

|

4″

|

100

|

229

|

229

|

190.5

|

157

|

24

|

8-Φ19

|

185

|

330

|

|

5″

|

125

|

356

|

254

|

216

|

185.7

|

26

|

8-Φ22

|

230

|

600

|

|

6″

|

150

|

394

|

279

|

241.3

|

216

|

26

|

8-Φ22

|

260

|

800

|

|

8″

|

200

|

457

|

343

|

298.5

|

270

|

29

|

8-Φ22

|

310

|

1000

|

|

10″

|

250

|

533

|

406

|

362

|

324

|

31

|

12-Φ25

|

350

|

1200

|

|

|

Type

|

Size(mm)

|

Dimension(mm)

|

|

|

inch

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

Z-Φd

|

H

|

W

|

|

Q41F/H/Y-300Lb

Q341F/H/Y-300Lb

Q641F/H/Y-300LbY

|

1/2″

|

15

|

140

|

95

|

66.5

|

35

|

15

|

4-Φ15

|

72

|

115

|

|

|

3/4″

|

20

|

152

|

117

|

82.5

|

43

|

16

|

4-Φ19

|

75

|

130

|

|

|

1″

|

25

|

165

|

124

|

89

|

51

|

18

|

4-Φ19

|

85

|

150

|

|

|

11/4″

|

32

|

178

|

133

|

98.5

|

64

|

19.5

|

4-Φ19

|

95

|

180

|

|

|

11/2″

|

40

|

190

|

156

|

114.3

|

73.2

|

21

|

4-Φ22

|

110

|

230

|

|

|

2″

|

50

|

216

|

165

|

127

|

92

|

23

|

8-Φ19

|

120

|

240

|

|

|

21/2″

|

65

|

241

|

190.5

|

149.4

|

104.7

|

26

|

8-Φ22

|

150

|

280

|

|

|

3″

|

80

|

283

|

210

|

168.5

|

127

|

29

|

8-Φ22

|

165

|

310

|

|

|

4″

|

100

|

305

|

254

|

200.2

|

157

|

32

|

8-Φ22

|

190

|

330

|

|

|

5″

|

125

|

381

|

279

|

235

|

185.7

|

35

|

8-Φ22

|

240

|

600

|

|

|

6″

|

150

|

403

|

318

|

270

|

216

|

37

|

12-Φ22

|

270

|

800

|

|

|

8″

|

200

|

502

|

381

|

330

|

270

|

42

|

12-Φ25

|

315

|

1000

|

|

|

10″

|

250

|

568

|

445

|

387.5

|

324

|

48

|

16-Φ29

|

380

|

1200

|

|

Type

|

Size(mm)

|

Dimension(mm)

|

|

|

inch

|

DN

|

L

|

D

|

D1

|

D2

|

b

|

Z-Φd

|

H

|

W

|

|

Q41F/H/Y-600Lb

Q341F/H/Y-600Lb

Q641F/H/Y-600Lb

|

1/2″

|

15

|

165

|

95

|

66.5

|

35

|

15

|

4-Φ15

|

88

|

115

|

|

|

3/4″

|

20

|

190

|

118

|

82.5

|

43

|

16

|

4-Φ19

|

98

|

130

|

|

|

1″

|

25

|

216

|

124

|

89

|

51

|

18

|

4-Φ19

|

105

|

150

|

|

|

11/2″

|

40

|

241

|

156

|

114.3

|

73.2

|

23

|

4-Φ22

|

135

|

180

|

|

|

2″

|

50

|

292

|

165

|

127

|

92

|

26

|

8-Φ19

|

155

|

240

|

|

|

3″

|

80

|

356

|

210

|

168.2

|

127

|

32

|

8-Φ22

|

175

|

280

|

|

|

4″

|

100

|

432

|

273

|

216

|

157

|

38

|

8-Φ25

|

210

|

330

|

|

|

6″

|

150

|

559

|

356

|

292

|

216

|

48

|

12-Φ29

|

340

|

800

|

|

|

8″

|

200

|

660

|

419

|

349

|

270

|

56

|

12-Φ32

|

400

|

1000

|

|

|

10″

|

250

|

787

|

508

|

432

|

324

|

64

|

16-Φ35

|

440

|

1200

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!