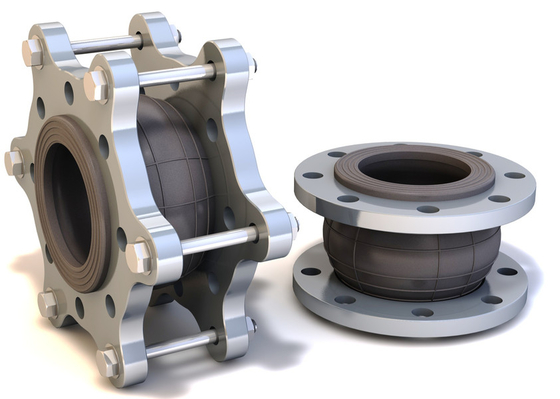

Model KXT-W Floating Flange Rubber Expansion Joints DN125, PN40,

Table of Materials

|

serial No.

|

Portion

|

Material

|

| 1 |

Main body

|

Polarized rubber

|

| 2 |

Lining

|

Nylon cord fabic

|

| 3 |

Frame

|

Hard steel wire

|

| 4 |

Flange

|

Mild steel

|

Technical Consition

|

DN mm

Nominal core diameter

|

32-300(11/4”) |

350-500(14”-20”) |

|

MPa(kg.f/cm²)

Working pressure

|

1.5(15) |

0.8(8) |

|

MPa(kg.f/cm²)

Bursting pressure

|

4.5(45) |

2.4(24) |

| Vacuity K Pa(mmHg) |

86.7(650) |

| Applicable temp.℃ |

-15~+60 |

| Applicable media |

Air.Compressed air,water,sea water,hot weak acid,etc. |

| Both ends of the join can be arbitray deflected for free adjustment of axial or lateral displacement. |

Table of Main Paraneters of Nominal Core Dimerer,Length,Displacement Value and Flange

|

Nominal core diameter

DN

|

Length

L

(mm)

|

No.of bolt

n

|

Dinameter of bolt hole

d0 (mm)

|

Diameter of bolt hole canter circle D1

(mm)

|

Axial displacement

(mm)

|

Lateral displacement

(mm)

|

Angle of deflection

(α1+α2)

|

| (mm) |

(in.) |

long |

short |

| 32 |

(11/4) |

150 |

130 |

4 |

15 |

89 |

12 |

20 |

14 |

15° |

| 40 |

(11/2) |

150 |

130 |

4 |

15 |

98.5 |

12 |

20 |

14 |

15° |

| 50 |

2 |

150 |

130 |

4 |

19 |

121 |

12 |

20 |

14 |

15° |

| 65 |

(21/2) |

150 |

130 |

4 |

19 |

139.5 |

12 |

20 |

14 |

15° |

| 80 |

(3) |

150 |

130 |

4 |

19 |

153 |

12 |

20 |

14 |

15° |

| 100 |

(4) |

150 |

130 |

8 |

19 |

190 |

12 |

20 |

14 |

15° |

| 125 |

(5) |

150 |

130 |

8 |

22.5 |

216 |

12 |

20 |

14 |

15° |

| 150 |

(6) |

150 |

130 |

8 |

22.5 |

242 |

12 |

20 |

14 |

15° |

| 200 |

(8) |

150 |

130 |

8 |

22.5 |

298 |

12 |

20 |

14 |

15° |

| 250 |

(10) |

150 |

130 |

12 |

25.5 |

362 |

12 |

20 |

14 |

15° |

| 300 |

(12) |

150 |

130 |

12 |

25.5 |

432 |

16 |

25 |

22 |

15° |

| 350 |

(14) |

200 |

12 |

28.5 |

476 |

16 |

25 |

22 |

15° |

| 400 |

(16) |

200 |

16 |

28.5 |

540 |

16 |

25 |

22 |

15° |

| 450 |

(18) |

200 |

16 |

32 |

578 |

16 |

25 |

22 |

15° |

| 500 |

(20) |

200 |

20 |

32 |

634 |

16 |

25 |

22 |

15° |

Flange drill :ANSI 150LB

Please kindly ignore the follow informaiton

FEATURES

• Iron strainers are complete with Flat Face (Series 125YF) or Raised Face (Series 250YF)

flanges in accordance with ASME B16.1.

• Strainer body meets applicable ASME Standard.

• One piece cast body.

• Strainers equipped with bolted cover flange that utilize a flat gasket seal.

• Low pressure drop.

• Upper and lower machined seats.

• 304 SS perforated screens are standard.

• Drain/Blow-off connection furnished with plug as standard.

• Generous screen area and properly proportioned straining chamber to minimize initial pressure

drop while maximizing time between cleanings.

• Compact end to end dimension.

Brief introduction:

The strainer may be used on all types of pipelines to collect granulated foreign substances and

contaminants collected. It can improve the clearance in the medium, and prolong the life of valves

and other equipments. It is suitable for wafer, petroleum and steam.

Mail part & material

Body: gray cast iron, cast iron, ductile iron

Filter: stainless steel

O-ring: NBR

Technical Specification

- Nominal diameter:65~500mm

- Nominal pressure:1.0/1.6/2.5Mpa

STRAINER INSTALLATION INSTRUCTIONS

A . Ensure all machined surfaces are free of defects and that the inside of the

strainer is free of foreign objects.

B . For horizontal pipelines, the strainer should be installed so that the drain

connection is pointed downwards.

C . For flanged end strainers, the flange bolting should be tightened gradually in

a back and forth clockwise motion.

D . Once installed, increase line pressure gradually and check for leakage around joints

E . If the strainer is supplied with a start-up screen, monitor pressure drop carefully.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!